CIRCALGAE – webinar summary

On October 26th, CIRCALGAE project’s partners held the first workshop in a series of events to be organized throughout the project. The event was held as a hybrid workshop, organized by CEVA and AQUIMER. It gathered project partners and stakeholders in Lille, while also allowing all interested parties to attend online, with close to 200 registered participants.

The workshop focused on seaweed harvesting and cultivation in Europe, providing perspectives from European stakeholders on seaweed supply and value chains.

The workshop started with a number of key facts on the seaweed sector in Europe. While global seaweed production exceeds 35 million tons according to FAO, Europe is still a small player, representing 1% of the global production. Another European specificity is its strong reliance on wild seaweed harvesting, with only a small fraction (<1%) of European production currently cultivated. Excerpts of CIRCALGAE report on European algae production and markets (to be published in 2024) were also presented (species, volumes, applications, …), illustrating the diversity of species and value chains.

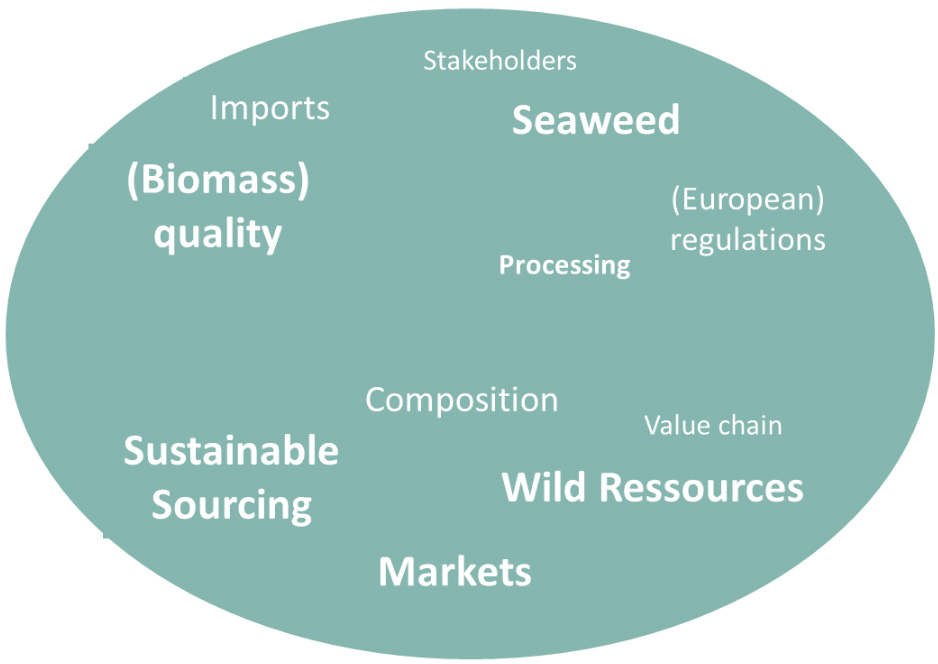

However, for a company, the choice of using harvested or cultivated seaweed is driven by a broad diversity of factors and constraints. These drivers range from availability of the biomass to economics, while taking into account other aspects such as seaweed composition, regulations or sustainability.

Drivers of selection between cultivation and harvesting

The workshop gave the floor to various European stakeholders across the seaweed sector.

The workshop started with an introduction of CIRCALGAE project by its coordinator Amparo Jiménez Quero. It was followed by a presentation of key facts on the seaweed sector in Europe (Ronan Pierre – CEVA, France)

Jehane Prudhomme, from Brittany’s Regional Committee for Maritime Fisheries and Marine Farming (France), illustrated the necessary balance between preservation of the environment and socio-economic development, when regulating wild seaweed stocks usage.

Göran Nylund, from Nordic Sea Farm (Sweden), and Mathilde Lemoine, from Algolesko (France), described their recent developments on marine farming of Saccharina latissima and Ulva. Beyond technical aspects, they stressed the need for scale-up, downstream processing and optimization, to allow environmentally and economically sustainable industrial models. Simon Haughom, from Alginor (Norway), also showed how novel integrated processes and biorefinery can support new economic models based on European seaweed.

Lastly, Mark Williams, from Ocean Harvest Technology (Ireland), and Cristina Fernandez Moure (Spain), from CEAMSA, showed how a diversity of seaweed sourcing can be necessary to support industrial models (You can find the answers to the questions asked during the event below the replay). This diversified sourcing allows to benefit from the diversity of compositions of various species and provides raw materials throughout the year. It can also be an answer to increasing tensions on cultivated or harvested biomass, subject to climatic events, climate change or diseases. But biomass supply (volumes and cost) also remains a key driver, and decision factor between European and imported species.

Interactive questions sessions with the speakers were also organized for in presence and online attendees.

Workshop presentations :

- CEVA (Centre d’Etude et de Valorisation des Algues)

- CRPMEM ( Comité Régional des Pêches Maritimes et des Elevages Marins de Bretagne)

- Nordic SeaFarm

- CEAMSA

- Alginor

Watch the replay of the workshop below :

Questions for Cristina Fernandez Moure of CEAMSA :

- Have you done anything with the red colorant phycoerythrin from these seaweeds? Are you planning to do? No, we didn’t make any project for colorant extraction from the seaweeds.

- Can you also use milled seaweed in your process? Depending on the seaweed type, we can apply different types of milling: 1) dried milling before extraction (this also helps to separate the leaves); 2) wet milling during the extraction (the mixing device used during extraction also disintegrate and cut the seaweeds). The milling process is applied for maximizing the yield of the process.

- How do you perform long-term preservation for seaweeds? The suppliers of the seaweeds ensure a % of salts and % moisture in the dried seaweed sent to us. The low moisture and a certain salt content help with the preservation. Depending on the seaweed, the maximum storage time is different. Some seaweeds lose more functionality than others with long storage time.

- After drying, how does the cleaning process look like? Drying is applied through the extracted carrageenan. The result of the drying is the carrageenan fibres, chips or pellets (depending on the process). In the semi refined process, where we don’t apply a filtration process, several cleaning steps are applied in the seaweeds during the wet process for ensuring the removal of the impurities.

- What are your ideas or perspectives of innovation in the extraction process? Our innovation on carrageenan extraction is focused on two main ways: 1) raw material- new sources of seaweeds; 2) process- we introduce continuously innovative process focused on the drying, milling, co-processing with other ingredients or hydrocolloids, filtration, pre-treatments before extraction, mechanical process that boost the functionality of the fibres etc. (of course, more detailed information is part of our know-how)